FRYER OIL

FILTRATION MONITORING

Filtering fryer oil is a necessity. But your kitchen is beyond busy. How can you ensure true consistency across locations every single day?

We know that fryer oil is one of the most expensive components of food preparation. That's why our restaurant monitoring system is crucial to protecting your bottom line. Better cost management coupled with enhanced quality control means a thriving kitchen.

Whether it’s a customer’s first visit or the fiftieth, the meals you serve need to have exceptional flavor and quality. The best way to exceed customer expectations is with a fryer oil filtration system. It allows you to standardize your filtration schedule, removing contaminants that affect the color, taste and smell of your food—only and always when appropriate. Not only does a restaurant monitoring system ensure the best oil ROI, but most importantly, it leaves your customers satisfied time and time again.

Our online, subscription-based fryer Filtration Monitoring system tracks the frequency and duration of filtration activities. Any deviation from the standard schedule will prompt an email alert, ensuring that you always know what’s happening in your kitchen.

Better Oil Filtration Means Happier Customers

The meals you serve should have consistent flavor and quality. The best way to ensure these standards stay high is to implement regular fryer filtration practices. A standard filtration schedule removes contaminants that can affect the color, taste and smell of your food. Our Fryer Filtration Monitoring system tracks both frequency and duration of filtration activities.

- Improves food quality

- Enhances employee accountability

- Drives operational consistency across your organization

- Increases your visibility to actionable information

- Improves cost management by optimizing oil usage

The Only Ones With Web-Based Filtration Monitoring

Access to your custom web portal is included and shows details such as actual filtration start and stop times. This will help you spot and react to trends in your organization’s oil management practices to enhance your quality control and employee training.

24/7 Email Alerts

Filtration noncompliance alerts are sent when a location has not followed standard operating procedures. This real-time reporting helps operators quickly take appropriate action before customer experience is affected.

Putting the “S” in SOPs

Implementing proper filtration helps ensure reliable quality and allows you to avoid unnecessary oil changes. With our Filtration Monitoring system, proprietary sensors are placed inside your fryers. We then configure the system to match your filtration standard operating procedures. We handle all the details and maintenance with no disruption to your operations.

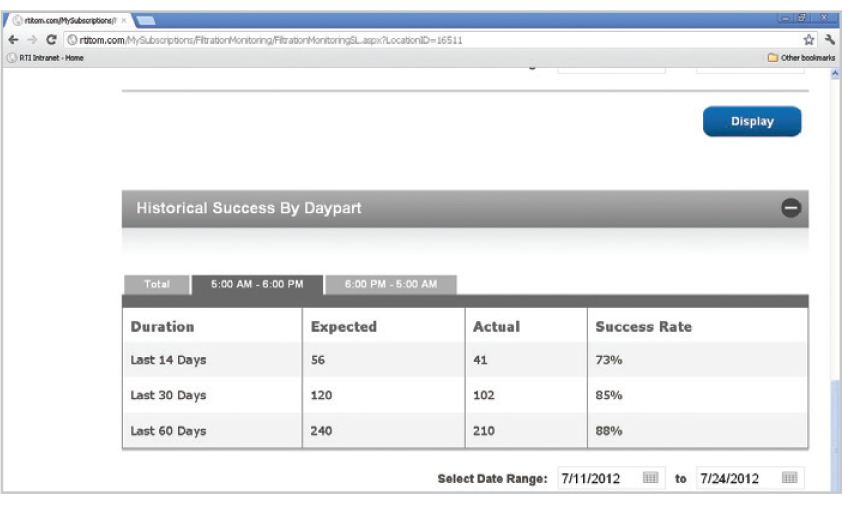

KEY PERFORMANCE INDICATORS

Easy-to-understand performance summary demonstrates how successful each location is at following established filtration procedures.

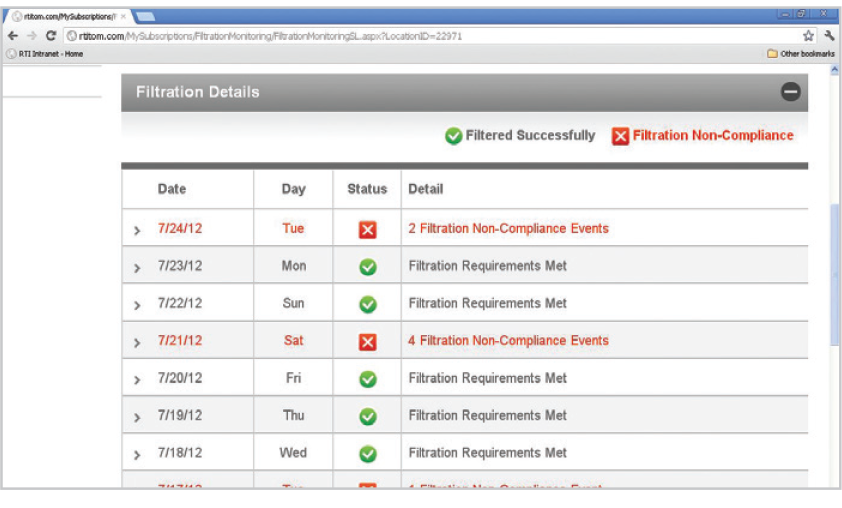

FILTRATION DETAILS

Drill down into specific dates to view actual filtration activity.

IDENTIFY TRENDS

Quickly determine where consistent areas of failure occur so corrective action can be taken.