1-3 mils

How Do Premera Coatings Work?

The Science Behind Premera Coatings

4 Factors Make our Coatings Work

(chemistry can get complicated — we will break down the concepts)

1. Our Coatings Chemically Bond with the Surface

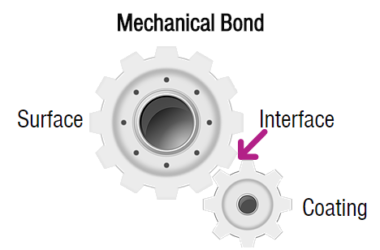

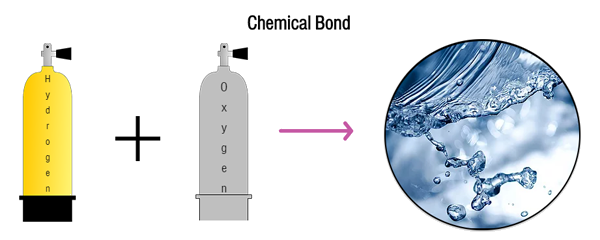

Premera Coatings establish chemical bonds with a surface. A chemical bond means that the molecules that make up our coating are chemically reacting with the molecules of a surface. In a mechanical bond, a coating fills the pores and micro spaces of a surface and then gets locked in place once the coating hardens, similar to two gears fitting together. Chemical bonds are different than mechanical bonds because chemical bonds cause a coating to actually become part of the surface. To demonstrate this idea, let’s look at water — hydrogen and oxygen. Hydrogen alone is a gas at room temperature and has uses such as filling balloons and fueling rockets.

Oxygen is a gas at room temperature and is used in industrial processes such as welding and steel production. Chemically bond the two together and they become water. Our coatings chemically bond with ANY surface they are applied to, creating an entirely new, super protective surface. Once cured, our coatings do not delaminate or flake off because the coating and the surface have become one.

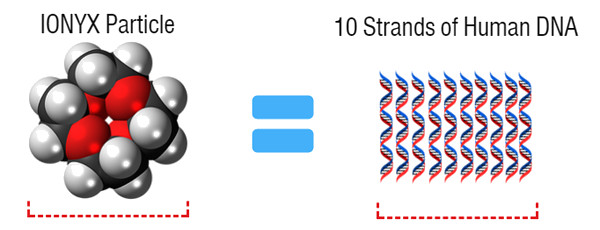

2. Our Particles Are Very, Very Small — Nano Small

When it comes to coating a surface, using extremely small particles has an advantage. Smaller particles can wet a surface better. Wetting refers to how much physical contact there is between a coating and a surface. This is largely why abrading a surface is recommended before coating a surface. Abrasion increases surface area, meaning there is literally more surface to be contacted than before the abrasion. Most coatings need larger spaces created from abrasion because they are not able to effectively fill the smallest surface pores and spaces. This is an issue because a coating can’t fully protect a surface if it can’t fully contact a surface. Using small particles eliminates gaps in the coating-to-substrate interface. This means full contact with the surface and therefore full protection.

How small are our particles? Take the width of a single strand of human DNA. Multiply by 10. You get the width of the particles our coatings are made of. Our coatings have extreme wetting ability because they have a high degree of contact with the actual molecules of the surface. This aspect alone is quite difficult for a coating to achieve. We take it one step further and chemically bond with surface molecules, creating a change in the molecular makeup of the surface.

3. Our Coatings Convert Surfaces into Quartz

Our small particles completely cover a surface and these particles then become part of the surface from their chemical bond, but what are those small particles made of and what are we actually turning the surface into? The answer is a modified Quartz. Our innovative chemical processes turn solid Quartz into a liquid, and once applied, it bonds to the surface and hardens back into its original form. Quartz has several useful properties that make it ideal for a surface coating. Quartz does not break down from the environment, is very hard and durable, and is very resistant to a wide range of chemicals. Aesthetically, it is crystal clear, makes surfaces much easier to clean, and prevents fading and decay. Nearly any surface or asset will see a dramatic increase in effective lifespan once converted to Quartz.

4. Premera Coatings are High Performance, NOT Highly Toxic

In today’s marketplace, it is not enough to just be effective. There are plenty of effective chemistries in the world that are unfortunately also extremely toxic and unsafe. For too much of human history, people just looking for something that solves their problems have been subjected to toxins causing anything from blindness to cancer. Keeping the people who have to use these coatings safe has been a major priority of ours since we began. Our coatings follow and beat the toughest environmental guidelines in the United States – the South Coastal Air Quality Management District. All of our coatings are under 100 grams per liter VOC and are MAS Certified Green.

To summarize, Premera Coatings:

Are very durable

Are corrosion resistant

Are UV resistant

Are chemically resistant

Are abrasion resistant

Are temperature resistant

Are extemely hard

Have excellent adhesion to substrate

Are easy and convenient to apply

Are environmentally safe (low to no VOC’s)

Have high cross-link density internally

Have high cross-link density with the substrate

VS

Traditional Petroleum Products

Inorganics do not fade or yellow, extreme environmental wear resistance

Organic components break down by nature, designed obsolescence

Extremely low to no VOC work with and exceed regulation

Medium to high VOC fight regulation to stay in market

5+ mils (higher cost / sq. ft.)

7.5+ Mohs

5-6.5 Mohs

Covalent bond (becomes part of the surface)

Sticks to surface like glue

3-5+ years*

1-3 years*

Inorganic, Quartz

Organic, Plastic

*Depending on wear conditions

Disruptive technology benefits society at the expense of slower moving industry giants

Where Do You Go From Here?

Notable Partners